Modular stand construction is full of clever solutions. BeMatrix, Aluvision, Octanorm: they’re all systems designed for quick, tool-free setup. At least… until it’s time to install the fabric.

Because right where the frame profiles meet, in corners, intersections, T-junctions, the silicone edge of your fabric doesn’t quite fit into the groove. So you end up trimming it. Usually last minute. With a utility knife. In a rush. On the show floor.

Sounds familiar?

Enter Van Straaten’s smart cut-out service

We do things differently. At Van Straaten, we deliver your silicone edge graphics with the cut-outs already in place. Wherever your frame profiles meet, we leave out a small section of the silicone edge. More importantly, we finish the ends on both sides of the cut-out with reinforced stitching. This prevents fraying, even after multiple uses.

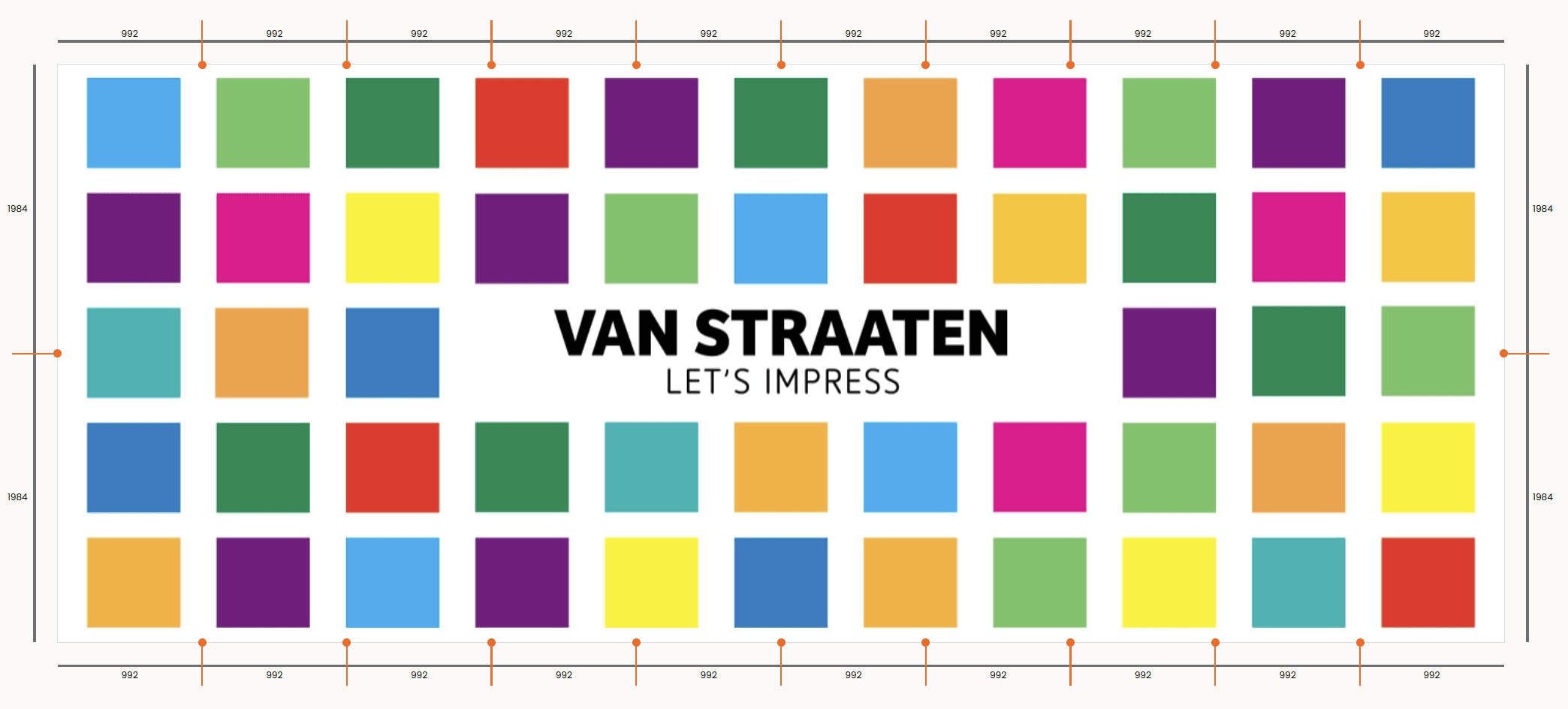

Just indicate the cut-out positions in your print file, like in the image below, and we’ll take care of the rest in production.

Why it makes your life easier

- Faster, more efficient setup: No more messing around with knives or scissors. The fabric fits perfectly right away. That saves time and money. The faster your team builds, the more square meters you can deliver with the same crew, which means better margins. You also cut down on labor costs, since the on-site work is faster and easier.

- Safer installation: Especially for larger stands, where graphics are mounted above 250 cm, it’s safer not to cut fabric while standing on ladders or scaffolding. Pre-cut fabric means fewer risks during installation.

- A cleaner finish: No frayed edges or crooked cuts, just a neatly finished fabric that fits your frame like a glove. Even in complex setups.

- Longer lifespan: Once you’ve cut into a graphic yourself, chances are it’s only good for one show. With our finishing, your print is ready for multiple uses.

- Fewer mistakes: You know exactly where the cut-outs are and that they’re placed correctly. No guessing or last-minute improvisation on-site.

- Time savings that add up: One of our clients tracked how much extra time their team spent making cut-outs during build-up. The result? The time saved by using our cut-out service was greater than the extra cost. A smart investment all around.

- Do more with fewer people: Cut-outs make large-format graphics easier to install. Because the silicone edges are precisely interrupted where needed, one person can install even very large prints without assistance. We’ve seen examples of 4 by 27 meter graphics mounted by a single person. It gives your team more flexibility and makes on-site setup more efficient.

Smart and sustainable

Whether you’re working with a simple back wall or a maze of frame structures, this service brings peace of mind during setup. And since your graphics last longer, it’s a more sustainable choice as well.

Ready to try our cut-out service?

Just mention it with your next order. If you use our order portal, you’ll automatically see the question “Would you like to have the tendons cut?” when ordering SEG fabrics. Answer “yes” and upload your cut-out diagram through the cart or the uploader. Like this:

We’ll make sure your fabric arrives build-ready. No fraying, no knives, no stress.

Questions? Give us a call at +31 23 555 18 61 or send us your file – we’ll be happy to take a look.